Specializing in manual and automatic handling, we protect against corrosion and ESD while prioritizing ergonomics, durability, and sustainability. Our customized projects improve cycle time, cost efficiency, and pack density, ensuring superior protection and cleanliness. We optimize material flow between plants, enhance packing density, reduce logistics costs, and promote pool packaging containers for operational excellence. Committed to sustainability, we integrate CSR regulations with innovative practices, linking eco-consciousness and packaging efficiency. Explore our durable, lightweight plastics for trays, blisters, boxes, and more.

Embracing Sustainability in Packaging

In today’s dynamic business environment, sustainability in packaging is a paramount concern, with Corporate Social Responsibility (CSR) regulations shaping industry norms. The intersection of sustainability and packaging emphasizes environmental awareness and compliance with regulatory frameworks, promoting ethical business practices.

As businesses strive to diminish their carbon footprint and advocate for eco-conscious practices, the packaging sector assumes a pivotal role in driving this transformative journey. Innovations in materials, design, and production processes are paving the path for greener alternatives that prioritize recyclability, reusability, and biodegradability.

Adhering to CSR regulations serves as a guiding beacon, directing companies toward ethical and sustainable packaging practices. By embracing these regulations, organizations not only mitigate environmental impact but also bolster brand reputation, cultivate consumer trust, and foster long-term value creation.

Embracing sustainability in packaging requires a comprehensive approach across the entire product lifecycle, from inception and manufacturing to end-of-life solutions. As businesses navigate the complexities of CSR regulations, they could innovate, collaborate, and lead the movement toward a more sustainable future for packaging and beyond.

Reduce

Reuse

Recycle

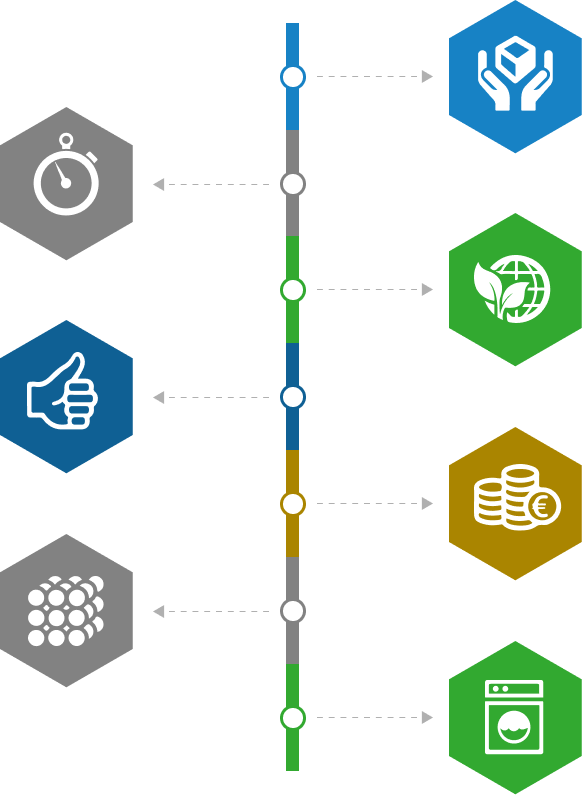

Packaging engineering KPIs

Our projects prioritize ergonomics, cycle time optimization, durability, cost efficiency, sustainability, pack density, damage protection, and cleanliness.

Each project embodies a holistic strategy, ensuring synergy between internal and external packaging. Meticulous alignment with production line specifications and logistical demands from inception to delivery is paramount. Engaging in the design phase early paves the way for seamless implementation and unparalleled success.

Embark on a Packaging Journey Redefined by Innovation:

Our solutions transcend mere product wrapping; they epitomize creativity and forward-thinking. Each package tells a story of ingenuity, crafted to elevate your brand and captivate your audience. Explore a world where packaging transcends convention; where every design is a masterpiece of innovation, meticulously tailored to meet your unique needs. Join us in reshaping the future of packaging, one groundbreaking solution at a time.

Supply Chain Optimization

Unveiling the Future of Packaging Engineering: Our solutions redefine industry standards with unparalleled innovation. Designed by engineers for engineers, our packaging transcends functionality to embody precision, efficiency, and creativity. Supply chain managers, production managers, quality managers, and designers understand the critical role packaging plays. Enter a realm where every detail is methodically crafted to enhance not just products, but the entire supply chain. Explore a partnership where innovation meets expertise, reshaping the world’s view of packaging. Welcome to a revolution in engineering excellence.

Industrial Packaging Development

Requirements

Identify the specific needs of the product being packaged, considering factors like fragility, size, weight, and transportation conditions.

Research

Research different types of packaging materials and designs that would best suit the product and its requirements.

Concept

Propose the packaging type that most resembles the parameters selected by the client’s engineering team.

Prototyping

Create prototypes to test the functionality and effectiveness of the packaging design before full-scale production.

Testing / Validation

Conducting thorough testing in a lab or field is essential to ensure packaging is durable, protective, and compliant with industry standards for transportation and storage. Packaging validation goes beyond this, ensuring that the packaging meets the customer’s specific requirements, including durability, ergonomics, functionality, and regulatory compliance, before the product is launched.

Costs / Regulations

Evaluate the cost implications of the proposed packaging solutions to ensure their economic viability. Additionally, ensure that the packaging design aligns with relevant regulations and standards, particularly when shipping internationally.

Production launch

Requirements

Identify the specific needs of the product being packaged, considering factors like fragility, size, weight, and transportation conditions.

Research

Research different types of packaging materials and designs that would best suit the product and its requirements.

Concept

Propose the packaging type that most resembles the parameters selected by the client’s engineering team.

Prototyping

Create prototypes to test the functionality and effectiveness of the packaging design before full-scale production.

Testing / Validation

Conduct thorough testing in a lab or in the field to ensure the packaging is durable, protective, and meets industry standards for transportation and storage. Packaging validation, however, involves ensuring that the packaging of a product meets the customer’s requirements, such as durability, ergonomics, functionality, and regulatory compliance before the product is launched.

Costs / Regulations

Evaluate the cost implications of the proposed packaging solutions to ensure they are economically viable.

Ensure that the packaging design complies with relevant regulations and standards, especially if shipping internationally.

Production launch

Long-Term Commitment

By nurturing enduring partnerships with our customers, we nurture a collaborative environment where together, we establish measurable objectives aimed at conserving resources and enhancing performance. This shared commitment not only drives sustainable practices but also yields mutual benefits that transcend traditional business relationships.

About us

With over 30 years of experience in the packaging industry, I specialize in delivering customized solutions for industrial clients worldwide. My extensive experience covers diverse applications and a wide array of materials, allowing me to navigate their advantages and limitations adeptly. Embracing a collaborative ethos, I thrive on working closely with colleagues and clients to understand their needs deeply. My commitment to long-term partnerships is underscored by measurable targets aimed at resource conservation and enhanced performance, fostering sustainable practices and mutual benefits beyond traditional business relationships.